[drawattention ID=”109″]

Capabilities

200,000 Square Feet of

Manufacturing Capabilities

- Machine Shops

- Inventory Control

- Metal Cutting & Tube Bend

- Mobility/ATP Test Track

- Vibratory Deburr and Fabrication Shop

- Top Coating

- Welding Shop

- Additional Facilities

Machine Shops

- CNC machining centers 3-4-5 axis, horizontal and vertical operations with palletized flexible manufacturing systems (FMS) for 24/7 operation

- Lathes with a capacity of up to 14” Hollow Spindle and 12-foot centers

- Traveling column vertical machining with 212-inch travel for high-speed machining of extremely long workpieces.

- Five axis Vertical Machining Centers utilizing trunnion-style rotary/tilt table and fitted with 12 pallets.

- High-speed horizontal centers w/40 pallets and 60 tool magazines

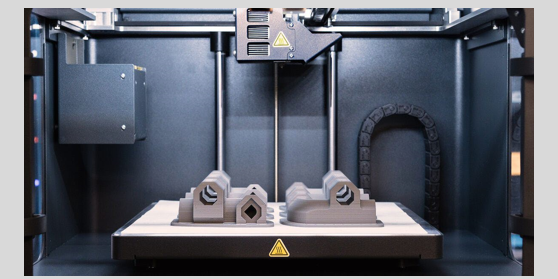

- 3D Metal Printing – fast tooling times – on-demand part replacements – design freedom of unattainable parts.

Inventory Control

Our warehouse facilities provide storage for all manufactured parts as well raw materials and hardware storage. We also can provide temporary storage for our customers providing them a logistical advantage in meeting shipping demands. Our facility utilizes the latest ERP systems and advanced shipping notification (ASN) processes.

Metal Cutting & Tube Bend

- Automatic horizontal 20” x 20” rectangular and 20” round, vertical tilt frame band saws.

- Eaton Leonard CNC hydraulic tube bender capacity 1.75 diameter x 20’ long.

Mobility/ATP Test Track

Certified test track to provide mobility tests on the C-17 Globemaster III ground support trailers as well as Acceptance Test Procedures (ATP) on various munitions trailers including the MHU-141 and MHU-110.

Vibratory Deburr and Fabrication Shop

3,500 sq. ft. deburr/fab shop equipped with:

- Automated vibratory deburr cell with four vibratory compartment rotary hoppers.

- 15’ horizontal screener shake conveyor and a 4′ x 6′ rotating media turnstile with four compartments for the different media types with a total capacity of 1400 cu. ft.

- Shear and Press Brake capacity for all size raw materials with brake capacity to 150 tons.

- Flame cutting capability for materials up to 60″ x 120″.

Top Coating

The company has two paint booths on-site. One provides environmental quality rear draft operations.

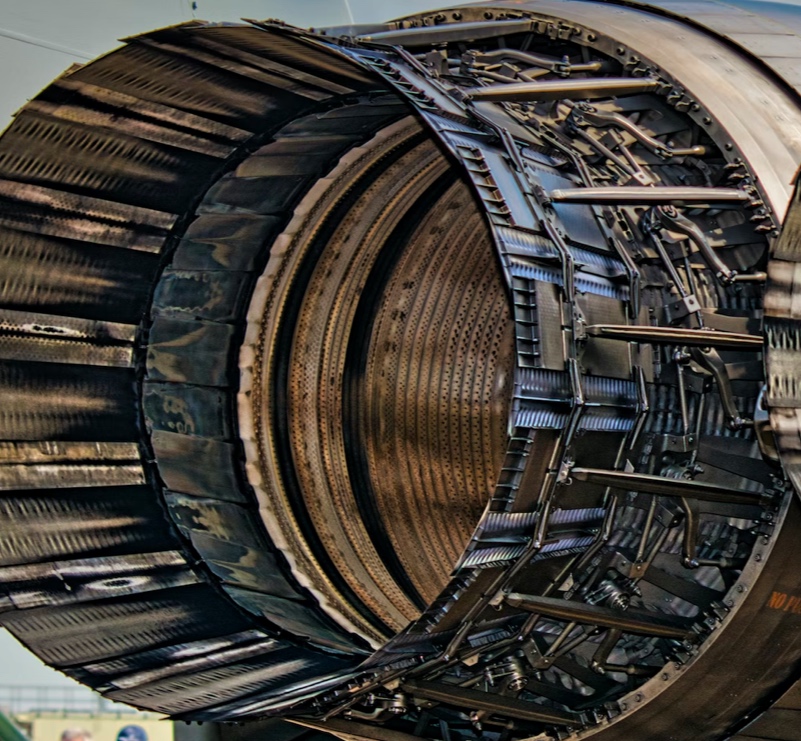

- Topcoats in accordance with current industry and military specifications.

- MIL-PRF-23377 and MIL-C-28285 for both aerospace and military requirements.

- Facility can house components weighting up to 20,000lbs.

- Environmental quality front draft spray booth capable of housing small to medium proportional components on universal adjustable racking system.

- 600 sq. ft. integrated pre-engineered blast room fitted with media recovery and reclamation system.

- Dust collector designed for multiple abrasives i.e., steel grit, garnet, aluminum oxide, plastic, and sand.

- 100 sq. ft. 96” Wheelabrator swing table with shot blast; the footprint is 12’ x 17’ x 19’.

Welding Shop

27,000 sq. ft. with 16 welding stations:

- Welding disciplines for steel, stainless, aluminum, using TIG, MIG, Arc, oxygen and acetylene.

- Ceiling height of twenty-five feet with a five-ton overhead bridge crane.

- All welders are certified to American Weld Standards

Additional Facilities

27,000 sq. ft. with 16 welding stations:

- 45,000 sq. ft. Assembly building for sub-assembly and end item completion and testing

- R&D facility with separate wood mill shop certified for wood packing materials for international trade.

- 6,000 sq. ft. machine storage building used for overflow.

- 4,000 sq. ft. secured building approved by DCMA storage.

- 10,000 sq. ft. overflow CNC machine facility